Advancing Glass Lubrication Technology

The Glass Business of TotalEnergies USA, Inc. is the manufacturer and worldwide supplier of Kleenmold® lubricants and coatings used in the glass container industry.

The Kleenmold name name represents a line of products dating back to 1938 when Kleenmold #1 was made for the Metro Glass Factory in Jersey City, New Jersey.

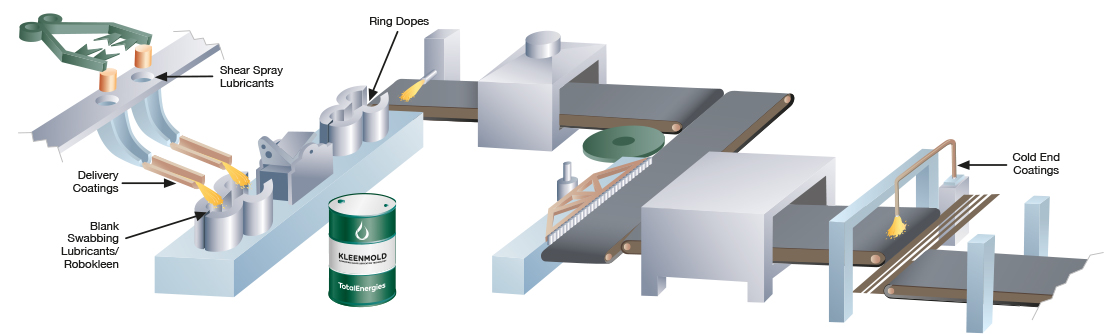

Over the years, the Kleenmold range has grown with the glass industry and currently many different lubricants, coatings and release agents from shear sprays to cold end coatings are available. Kleenmold products have been manufactured under strict quality control guidelines in our Linden, New Jersey USA production facility ensuring consistent, high-quality products. Many products have NSF (food grade H-2 or H-1) approval.

Kleenmold Swabbing Compounds are recognized as the industry standard worldwide. In addition to Kleenmold, TotalEnergies USA offers a complete range of hot end lubricants with brand names such as Biosol, Kleenkut, Glassflow and Kleenoil. Our lubricants and coatings have a significant impact on productivity and percent pack. Through cooperation with the worldwide glass industry, we have been able to test and refine all of our products to lubricate cleanly, eliminate defects and meet the demands of the evolving industry.

OUR TECHNICAL SERVICES MAKES THE DIFFERENCE

Our technical team is dedicated to formulating new products that are easier to use, environmentally-friendly and more efficient for the bottle-making process. The TotalEnergies Glass Team is available to work with you and your company individually to solve any lubricant-related concerns. We provide a variety of services including:

- Shear Spray Condition Monitor Analysis

- Glass Defect Analysis

- Consumption Reporting

In addition to the above-mentioned services, we also offer personalized on-site Swab Schools in order to demonstrate the most efficient way to use a swabbing compound. For more information on an on-site swab school or a DVD, please contact your local distributor or one of our Kleenmold offices.

MAINTENANCE AND LUBRICATION SOFTWARE

One of the largest challenges in the management process is planning your lubrication and maintenance operations, and keeping a very tight control of costs. To streamline these complex tasks, TotalEnergies has developed TIG 6 software for managing your resources.

TIG 6 can be custom-configured to tackle the lubrication management needs of any glass manufacturing or food processing facility.

Key Features:

- Optimization of maintenance, scheduling and lubrication management for increased efficiency

- Stand-alone software allows you to monitor all your operations

- Complete range of parameters and analyses for lubricants

- Analysis of completemaintenance costs – lubricants, spare parts and labor

- Direct importing of comments and results of ANAC analysis

- Integrated document management

- Better quality and safety management

Easy to Use!

- Features a standard Windows interface plus a mobile version with barcode or RFID-based management for direct use on-site

- Operational after a short training session with your team, regardless of their degree of IT literacy

- Comprehensive support, user tips and technical assistance are always available

TIG 6 may not be available in all countries

An Unsurpassed Product Range

Our commitment to quality and unsurpassed customer service makes Kleenmold glass lubricants the right choice. TotalEnergies' Kleenmold product line includes lubricants and coatings for all glass applications:

- Shear Sprays

- Delivery Coatings

- Precoats

- Blanks Swabbing Lubricants

- Pressware

- I.S. Machine Lubricants

- Ring Dopes

- Mold Lubricants

- Blank Sprays

Swab stations are recommended for maximum performance of Kleenmold lubricants.