BERYLANE

Specialty Base Oils

TotalEnergies’ Berylane products are a range of high performance, biodegradable and low viscosity base oils widely used when fabricating metal working fluids. They are designed for a variety of, applications within the metal working arena, and deliver excellent washing and cooling action.

The outstanding purity of the Berylane range delivers characteristics critical to formulators when selecting base oils for metal working fluids, including:

- Non-VOC†

- Approved for indirect contact with food*

- A complete absence of odor and color

- Superior aging stability

- Mildness on the skin

Berylane’s excellent washing and cooling action is particularly important to operations such as Grinding, Honing and Electrical Discharge Machining:

- Berylane’s outstanding washing action keeps machine tools clean and removes filings and chips.

- Berylane’s excellent cooling action is needed to dispel the extreme heat generated by these operations.

The Berylane range is particularly suited for cutting and grinding applications that can only be formulated with low viscosity base oils. The range allows the formulator to select the best possible compromise between low viscosity, flash point and evaporation rate.

† according to CARB requirements)

* Berylane meets FDA 21 CFR 172.878 FDA 21 CFR 172.878 and FDA

21 FR 178.3620(a) requirements for indirect food contact

Technical Characteristics to Meet Your Needs

Berylane fluids do not stain, are crystal clear and odorless thanks to their outstanding purity. Their narrow boiling range ensures low evaporation rates and tailored flash points, reducing both fire risk and vapor formation on the shop floor.

- Berylane’s excellent aging stability, exceeding even synthetic isoparaffinic fluids, maximizes the service life of the metal working fluid.

- All grades are non-VOC according to CARB requirements and approved for indirect contact with food.

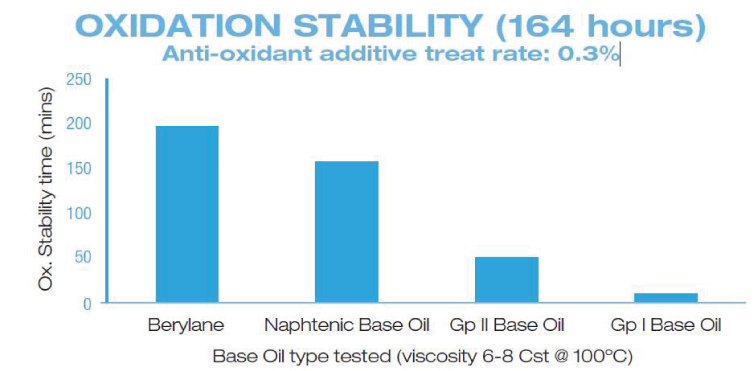

The Rotating Pressure Vessel Oxidation Test (RPVOT) is a test that determines the oxidation stability of an oil. RPVOT measures the actual resistance to oil oxidation whereas the other tests detect oxidation that is already present in the oil. The graphic (above/on the right) presents the results obtained after a RPVOT cycle under severe conditions (T° > 200°C, iron catalyst).

The Berylane Range demonstrates class-leading resistance under severe conditions for several hours before oxidization begins when compared to alternative technologies.

Indicative Values:

Typical values

| PROPERTIES | UNITS | METHODS | BERYLANE 210 | BERYLANE 235 | BERYLANE 260 | BERYLANE 270 | BERYLANE 320 |

|---|---|---|---|---|---|---|---|

| DENSITY AT 15°C (59°F) | kg/m3 (Lb/gal) | ASTM D4052 | 810 (6.76) | 820 (6.84) | 826 (6.89) | 829 (6.92) | 841 (7.02) |

| SAYBOLT COLOR | Unit color saybolt | ASTM D6045 | +30 | +30 | +30 | +30 | +25 |

|

BOILING RANGE: -INITIAL POINT |

°C (°F) | ASTM D86 | 205 (410) | 236 (457) | 257 (495) | 263 (505) | 315 (599) |

|

BOILING RANGE: -FINAL POINT |

°C (°F) | ASTM D86 | 241 (466) | 266 (511) | 300 (572) | 311 (592) | 375 (707) |

| FLASH POINT | °C (°F) | ASTM D93 | 80 (176) | 105 (221) | 121 (250) | 131 (268) | 167 (333) |

| AROMATIC CONTENT | mg/kg (ppm) | UV Internal method | <100 | <100 | <100 | <120 | <300 |

| BENZENE CONTENT | mg/kg (ppm) | ASTM D6229 |

<1 |

<1 | <1 | <1 | <1 |

|

REFRACTIVE INDEX AT 20° C (68° F) |

- | ASTM D1218 | 1.443 | 1.4513 | 1.4533 | 1.4554 | 1.4614 |

| ANILINE POINT | °C (°F) | ASTM D611 | 72 (162) | 80 (176) | 85 (185) | 86 (187) | 98 (208) |

| VAPOUR PRESSURE AT 20° C (68° F) | kPa | Calculated | 0.015 | 0.002 | <0.0001 | <0.0001 | <0.0001 |

|

VISCOSITY: AT 20°C (68°F) |

mm2/s | ASMT D445 | 2.46 | 3.73 | 5.80 | 7.39 | 17.40 |

| AT 40°C (104°F) | mm2/s | ASMT D445 | 1.67 | 2.40 | 3.70 | 4.33 | 8.70 |

| POUR POINT | °C (°F) | ASTM D97 | -50 (-58) | -33 (-27) | -20 (-4) | - 27 (-17) | 3 (37) |

Purity

|

FDA 21 CFR 178.3620 (B), WHITE MINERAL OIL |

-- | -- | X | X | X | X | X |

|---|

|

CARBON CHAIN LENGTH HSPA* DEFINED IN THE FRAMEWORK OF REACH* |

-- | -- | C11-C14 | C13-C16 | C15-C20 | C15-C20 | |

|---|---|---|---|---|---|---|---|

|

C.A.S. NUMBER |

-- | -- | 64742-47-8 (R) | 64742-46-7 (R) | 64742-46-7 (R) | 64742-46-7 (R) | 64742-55-8 |

Typical values provided are based on TSUSA’s current knowledge; TSUSA reserves the right to amend these figures.

Data provided on this table is issued in good faith to the best of our knowledge, but no warrantee, expressed or implied, is given.

*HSPA : Hydrocarbon Solvents Producers Association

*REACh : Regulation (EC) No 1907/2006

*R: Related C.A.S. number